Checking the test due date on your gas cylinder is a simple process that can be done in a few easy steps. The first step is to locate the test stamp or label on the cylinder. This stamp or label contains important information about the cylinder, including the test due date. It is usually located near the top or bottom of the cylinder, and it may be stamped directly onto the metal or attached as a label.

Once you have located the test stamp or label, you will need to decipher the information to determine the test due date. The test due date is typically indicated by a month and year, such as “03/2023” for March 2023. Some cylinders may use a different format, such as “03-23” for March 2023. It is important to note that different countries or regions may have different date formats, so be sure to familiarize yourself with the format used in your area.

If the test due date has passed, it is important to take immediate action. Using a gas cylinder that has expired can be dangerous and may result in accidents or leaks. In most cases, expired cylinders cannot be refilled or used, and they should be taken out of service. Contact your local gas supplier or cylinder testing facility for proper disposal or recycling options.

On the other hand, if the test due date is still valid, you can continue using the cylinder with peace of mind. However, it is important to keep track of the test due date and schedule a retest well in advance. Depending on the regulations in your area, gas cylinders may need to be tested every 5, 10, or 15 years. It is recommended to mark the test due date on a calendar or set a reminder on your phone to ensure you do not miss the deadline.

In addition to checking the test due date, it is also important to inspect the overall condition of the gas cylinder. Look for any signs of damage, such as dents, rust, or corrosion. If you notice any abnormalities, it is best to consult with a professional or contact the cylinder testing facility for further guidance. Regular maintenance and proper handling of gas cylinders are crucial for ensuring their longevity and safety.

In conclusion, checking the test due date on your gas cylinder is an essential part of maintaining its safety and compliance. By following the steps outlined in this blog post and staying vigilant about the test due date, you can ensure the safe and proper use of your gas cylinder for years to come.

Step 1: Locate the Test Date Stamp

The first step is to locate the test date stamp on your cylinder. The test date stamp is usually located near the cylinder neck or shoulder and is imprinted or stamped onto the metal surface. It contains important information about the cylinder, including the test due date.

When inspecting your cylinder, it is crucial to find the test date stamp as it provides essential information about the cylinder’s safety and compliance with regulations. The test date stamp serves as a record of when the cylinder was last tested and approved for use. This information is crucial for ensuring the cylinder’s integrity and preventing any potential hazards.

To locate the test date stamp, carefully examine the cylinder’s surface near the neck or shoulder. It is typically engraved or stamped onto the metal, making it easily visible. The stamp may include a combination of numbers and letters, representing the month and year of the cylinder’s last test.

Once you have located the test date stamp, it is important to decipher the information it provides. The date stamp will indicate the month and year of the cylinder’s last test, allowing you to determine its current validity. This information is essential for ensuring that the cylinder is within its recommended usage period and has not exceeded its test due date.

Additionally, the test date stamp may also include other relevant information, such as the testing facility or organization responsible for conducting the examination. This information can be useful for tracking the cylinder’s testing history and ensuring that it has been inspected by a reputable and accredited entity.

Remember, it is crucial to regularly check the test date stamp on your cylinder and ensure that it is within its recommended usage period. Using an expired cylinder can pose serious safety risks, as it may not withstand the required pressure or contain the contents securely. If you find that your cylinder has exceeded its test due date, it is important to have it retested or replaced to maintain safety standards.

By following this first step and locating the test date stamp on your cylinder, you are taking a proactive approach towards ensuring the cylinder’s safety and compliance. This information will guide you in making informed decisions about the cylinder’s usage, maintenance, and replacement, ultimately promoting a safer working environment and preventing potential accidents or incidents.

Step 2: Understand the Test Date Format

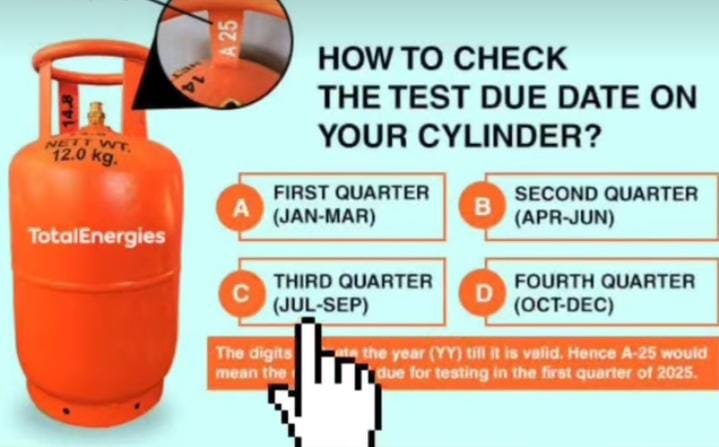

Once you have located the test date stamp, it is essential to understand the format in which the test due date is displayed. The test due date is typically represented by a combination of letters and numbers. The most common formats include:

- Month and year (MM/YY): For example, 06/23 indicates that the cylinder test is due in June 2023.

- Quarter and year (Q-YY): For example, Q2-23 indicates that the cylinder’s test is due in the second quarter of 2023.

- Year (YY): For example, 23 indicates that the cylinder’s test is due in the year 2023.

Understanding the format will help you interpret the test due date accurately.

It is important to note that different industries and regulatory bodies may have their own specific formats for displaying test due dates. For example, in the medical field, the test due date format may include additional information such as the day of the month or the specific time of day when the test is due.

Additionally, some industries may use a combination of formats to indicate different types of tests or inspections. For instance, a cylinder used in the aviation industry may have separate test due dates for its visual inspection and its hydrostatic test, each represented in a different format.

Understanding the test date format is crucial for ensuring compliance with regulations and maintaining the safety and integrity of the tested equipment or materials. It allows individuals responsible for conducting tests or inspections to accurately determine when the next test is due and take appropriate action in a timely manner.

Furthermore, being familiar with the test date format can also help in planning and scheduling future tests or inspections. By understanding how the dates are displayed, individuals can easily identify the chronological order of tests and prioritize them accordingly.

In summary, comprehending the test date format is a fundamental step in effectively managing and maintaining the integrity of tested equipment or materials. It enables accurate interpretation of test due dates, facilitates compliance with regulations, and assists in planning future tests or inspections.

Step 3: Calculate the Test Due Date

Once you have identified the test date format, you can calculate the test due date based on the information provided on the test date stamp. This step is crucial in ensuring that your cylinder remains safe and compliant.

Let’s dive deeper into the examples provided earlier to understand how to calculate the test due date:

Example 1: If the test date stamp displays 06/23, the test due date is June 2023. In this case, the month and year are clearly stated, making it easy to determine the due date.

Example 2: If the test date stamp displays Q2-23, the test due date is the second quarter of 2023, which typically falls between April and June. Here, the quarter is indicated, allowing you to narrow down the timeframe for the test.

Example 3: If the test date stamp displays 23, the test due date is the year 2023. While this example may seem straightforward, it is important to note that some stamps may only indicate the year. Therefore, it is essential to be aware of the specific format used.

Calculating the test due date is crucial to ensure that your cylinder is tested within the required timeframe. Failure to adhere to these guidelines can result in potential safety hazards and non-compliance with regulations.

By taking the time to understand the test date format and accurately calculate the test due date, you can prioritize the safety and compliance of your cylinder. This knowledge empowers you to schedule the necessary inspections or tests in a timely manner, ensuring that your cylinder remains in optimal condition.

Step 4: Schedule the Cylinder Test

Once you have determined the test due date, it is important to schedule the cylinder test well in advance to ensure compliance and avoid any last-minute hassles. Contact your gas cylinder provider or a certified testing facility to book an appointment for the test.

During the test, the cylinder will undergo a thorough inspection to assess its condition and ensure it meets the required safety standards. The testing facility will conduct various tests, such as a visual inspection, hydrostatic test, and leakage test, to ensure the cylinder is safe to use.

The visual inspection involves checking for any visible signs of damage or corrosion on the cylinder’s exterior. This is important as any visible defects can indicate potential weaknesses that may compromise the cylinder’s integrity.

The hydrostatic test is a critical part of the cylinder testing process. It involves filling the cylinder with water or another suitable test medium and subjecting it to high pressure to evaluate its strength and ability to withstand pressure. This test helps identify any potential leaks or weaknesses in the cylinder’s walls.

In addition to the visual inspection and hydrostatic test, the testing facility will also conduct a leakage test. This test involves pressurizing the cylinder and using a specialized solution or equipment to detect any leaks. It ensures that the cylinder is properly sealed and does not pose a risk of gas leakage.

Once all the tests are completed, the testing facility will provide you with a detailed report outlining the results of the inspection. If the cylinder passes all the tests, it will be certified as safe for use, and you can continue using it without any concerns. However, if any issues are identified during the testing process, the facility will provide recommendations for repair or replacement.

It is important to note that cylinder testing is not a one-time requirement. Depending on the regulations in your country or industry, cylinders may need to be tested periodically. Therefore, it is crucial to keep track of the test due dates and schedule the tests accordingly to ensure the safety of your gas cylinders.

Step 5: Maintain a Record

To stay organized and keep track of the test due dates for your cylinders, it is recommended to maintain a record. You can create a simple spreadsheet or use a digital tool to record the cylinder details, test due dates, and the date of the last test. This will help you stay on top of the testing schedule and ensure the cylinders are always safe and compliant.

When creating a record, it is important to include all relevant information about each cylinder. This includes the cylinder’s unique identifier, such as a serial number or barcode, as well as any additional details that may be useful, such as the cylinder’s size, type, or contents.

In addition to recording the cylinder details, it is essential to note the test due dates and the date of the last test. This information will allow you to easily identify which cylinders are due for testing and ensure that they are tested within the required timeframe.

By maintaining a record, you can also track the testing history of each cylinder. This can be useful for identifying any patterns or trends in the testing results, such as cylinders that consistently fail the tests or require more frequent testing.

Using a spreadsheet or digital tool to maintain the record offers several advantages. Firstly, it allows for easy sorting and filtering of the data, making it simple to identify cylinders that are due for testing or to generate reports on the overall testing status. Secondly, it provides a centralized location for all the information, eliminating the need to search through multiple documents or systems to find the required information. Finally, it enables easy sharing and collaboration with other team members or stakeholders who may need access to the cylinder testing information.

Regularly updating the record is crucial to ensure its accuracy and effectiveness. Whenever a cylinder undergoes a test, the record should be promptly updated with the new test due date and the date of the test. This will help you maintain an up-to-date and reliable record that can be used as a reference for compliance purposes or during audits.

In conclusion, maintaining a record of cylinder testing details is an essential step in managing the testing process effectively. By keeping track of the cylinder details, test due dates, and testing history, you can ensure that your cylinders are always safe, compliant, and ready for use.